7 New CAD Features to Explore in Mastercam 2025

- AMP Team

- Nov 21, 2024

- 3 min read

Mastercam Design is a computer-aided design solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Mastercam 2025 is here and elevates your machining experience with powerful toolpaths, flexible tool motion, and our most intuitive interface yet. Here are some top CAD features—and how they can help your shop.

1. Analyze Deviation

The engines that individual CAD systems use to generate geometry can produce models that vary from system to system. If you have to import information from other packages, you may need to identify deviation between imported entities and their Mastercam counterparts. Mastercam 2025 now includes deviation analysis that allows you to compare any combination of points, curves, surfaces, bodies, and faces.

The new Analyze Deviation function analyzes the differences between different kinds of entities and applies a color-coded “heat map” to the geometry to display deviations within the graphics window.

2. Modified Mesh Geometry

Mastercam 2025 no longer removes associated edited mesh geometry from a toolpath operation. Now, if you edit your associated mesh, there is no need to reselect your geometry; you only need to regenerate the toolpath, saving both time and money.

3. Nesting Results

Three new interface options are now available to improve the visibility of your nested parts in the Nesting Results dialog box. Select the White background and Black part geometry options to instantly view high contrast previews of your nested parts. You can also further adjust part definition by selecting a line width from the Line width drop-down menu.

4. Multiple Nesting Reports

Sometimes it’s important to compare nesting strategies to see which would work best for your setup. In previous versions of Mastercam, this required the extra step of renaming the XML in the ActiveReports Selection dialog box, or copying and renaming the file after you generated it. Now, Mastercam generates a unique, randomly named XML file each time you run a Nesting report, eliminating this extra step.

5. Control Processing Time for Solid Fillets

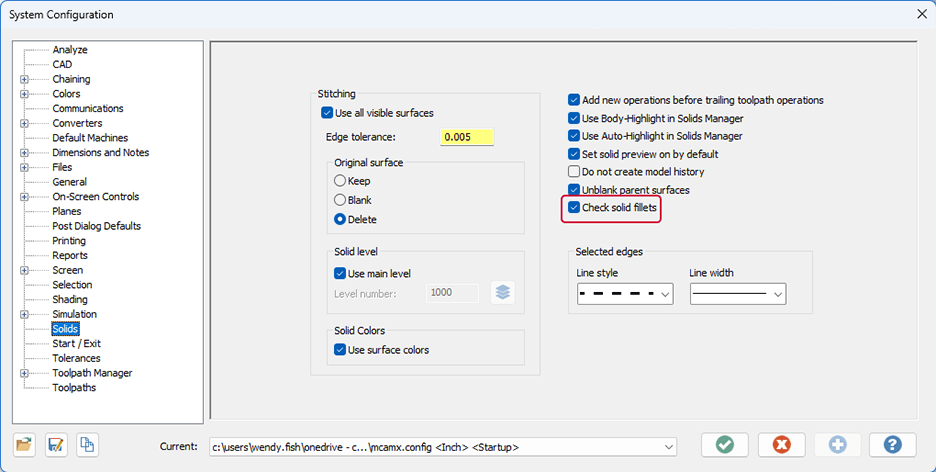

Modifying complex solids can be time-consuming due to the amount of validation Mastercam has to do to read the file and process the changes. To save your shop’s time, we have added the ability to control how Mastercam reads the filleted edges of your solids. Choose to either control this behavior globally for all your solids or locally for individual solid bodies.

Deselect the new Check solid fillets option to stop Mastercam from validating the blended edges of all solids, which can significantly reduce processing time.

The new Check Results controls allow you to override your system configuration settings whenever you feel it is necessary.

6. Duplicated Solids

In previous versions of Mastercam, if you needed to create multiple copies of a solid in the Solids Manager, it could be difficult to keep track of your results. To help you, Mastercam 2025 automatically renames duplicated solids according to Windows standards. Now when you duplicate a solid, Mastercam appends “-Copy” plus a number to indicate if there is more than one duplication.

When you copy a solid that has already been duplicated, Mastercam continues to add “-Copy” to the name of the solid.

Mastercam adds both types of duplicated solids to the bottom of the Solids History Tree. If you create multiple duplications of a solid model consistently, it is recommended that you give your solids unique names to minimize any confusion.

7. Define a Sweep Angle

Mastercam 2025 reduces the time you spend creating CAD for CAM by now allowing you to define a specific sweep angle when you use the Arc one entity and Arc one point methods in the Arc Tangent function. In previous versions, you would have had to adjust the arc in a separate step because the arc angle was predefined at 180 degrees.

Comments